The future of food packaging is guided by a few potent impulses. One is the expectation that it meets modern environmental norms. Another is global dictates slapped on businesses to reduce climate change. A third is the need to innovate, creating packaging that appeals to consumers while preserving food until it’s consumed. A fourth, in an increasingly competitive world market, is keeping costs down.

Accommodating all these elements is no easy task, especially when the brief for what makes a truly sustainable product is getting longer by the day. It used to be easy: do you sell drinks? Put them in aluminum or glass. Food? Then it’s paper or cardboard. These are four of the most widely recycled materials, so businesses delegated responsibility to consumers. Problem solved.

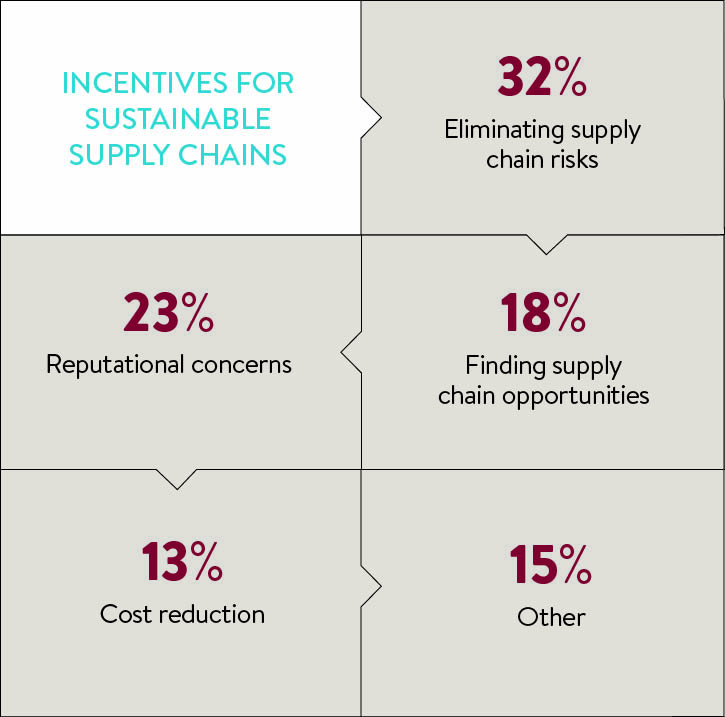

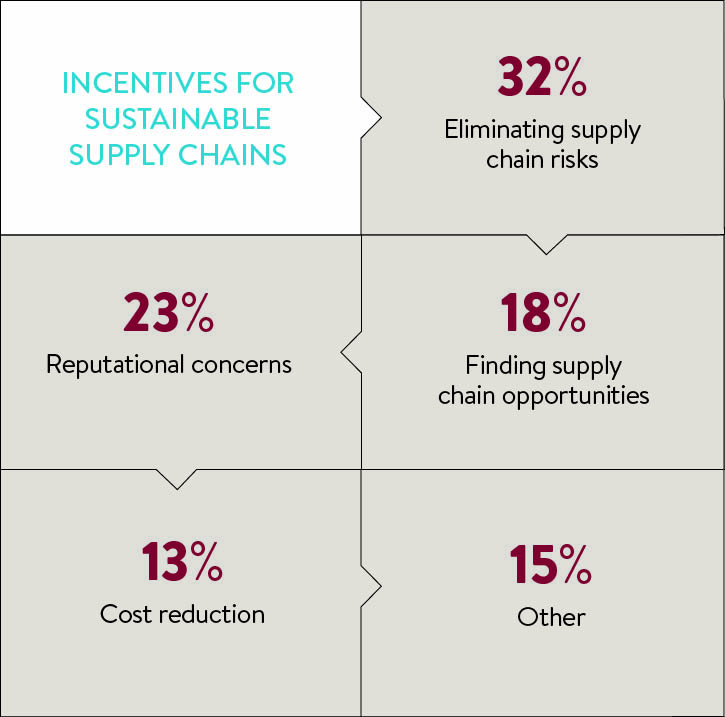

But now a big green magnifying glass is sweeping over the entire supply chain. Brands are de facto responsible for ethics in a process that starts with a field and ends with a fork. Where do you get your materials from? How are they manufactured? How are they shipped? Who’s working at the factory? It all counts.

Considering every element

“The trend right now is an holistic approach to sustainability, looking at the impact that innovations can have across the entire supply chain, rather than focusing only on developments within individual products,” says Fiacre O’Donnell, head of strategic development at glass manufacturer Encirc.

“It’s no longer enough to use recycled materials if the lorries bringing those resources to site are only half full or the manufacturing methods leave a huge carbon footprint. For true innovation to take place, every element of a supply chain and its bearing on the end-goal must be considered.”

Phil Wild, chief executive of British master papermaker James Cropper, adds: “There are two sides to the coin that must be considered – the sustainability of the products used for packaging in the first place and what happens to them after use.

“Paper is often a go-to choice for sustainable packaging because it can be recycled and reused many times. However, in the food industry, health and hygiene regulations must also be considered. This presents its own challenges, so innovation is crucial.”

From a consumer-facing standpoint, the drive to bring packaging into the 21st century is more carrot than stick. People don’t have time to research which companies have the cleanest supply chain, but when businesses shout loudly about good practice, sales go up.

In fact, it’s a golden chance to generate buzz completely out of kilter with the size of the brand. Ever heard of the Saltwater Brewery in Florida? Me neither. Yet it has just scored a global marketing slam dunk with the invention of new six-pack rings.

The rings are not made from plastic, which as we know ends up in the sea to be gobbled up by hapless turtles, birds and fish, but a combination of barley and wheat that are by-products from the brewing process. They are not just biodegradable, they’re edible.

A film explaining the invention was posted on the video-sharing platform Vimeo. In three weeks it accumulated 82,000 views. Type “edible six pack” into Google and Saltwater Brewery is all you get back. It’s the kind of marketing that takes businesses into the stratosphere.

Other organisations have captured varying amounts of positive press with their efforts to create edible or biodegradable products. Ooho!, from Skipping Rocks Lab, is a seaweed alternative to plastic bottles. In 2012 UK manufacturer Pepceuticals won a contract to develop an edible coating for meat, while Monosol, also based in the UK, has created a packaging film that dissolves harmlessly in water.

Ooho! by Skipping Rocks Lab, an edible alternative to the plastic water bottle, made from seaweed

Gillian Hopkinson, senior lecturer in marketing at Lancaster University Management School, says there is scepticism around these innovations that befits truly “out there” ideas, but this is healthy, and nevertheless it’s where the food and drink sector is headed.

“I think that we will see substantial growth in the area of edible and/or biodegradable packaging as creative thinking, technological knowledge and consumer insight combine to bring in effective packaging,” she says.

Innovation

In a humbler example, Dr Hopkinson points to pouches as a simple solution that has removed a lot of excess weight from packaging. First seen in Ella’s Kitchen baby foods some ten years ago, they are popping up everywhere in food and non-food products.

Pouches are popular because the benefits are easy to understand. It’s like double-strength cordials, which offer a simple equation: double the strength, halve the amount required to make a drink. Future innovations will need to mimic this simplicity to gain mass-market appeal.

“The crucial aspect of pouches is that consumers ‘get it’,” she says. “Shopping and storage at home become easier and there is less packaging to dispose of either through recycling or in the bin. So, the next generation of packaging must make sense for consumers.”

Aleyn Smith-Gillespie, associate director at the Carbon Trust, has seen plenty of activity in the innovation space, with companies approaching the problem of waste from several different angles.

“There are also quite a lot of companies looking at using more biodegradable or compostable packaging options made from organic materials,” he says. “But some companies are looking to make packaging more durable, rather than more easily disposed of, so that it can be returned and reused, or given a second life.

“We are starting to see increased use of novel materials such as bioplastics, which can be part of more circular approach to product packaging. Braskem in Brazil makes biopolyethylene from sugar cane which has identical properties and uses to polyethylene made from fossil fuels.

“Recent work we did with Polythene UK found that the carbon emissions absorbed from the atmosphere during the growing of the sugar cane can be greater than the emissions from manufacturing and transporting the biopolyethylene created, which means it is inherently carbon neutral. It is also fully recyclable.”

If the price is right, then innovations like this will be no-brainers for buyers in years to come. With the developed world increasingly concerned for the continued health of the planet, this future can’t come quick enough, says Dr James Cronin, lecturer in branding at Lancaster University Management School.

“Producers are expected to not just focus on packaging that preserves and communicates, they must also consider the impact it has on the world. As landfills swell, resources deplete and environments are degraded, the only option for a manageable future is sustainable packaging as a critical part of value-added practice,” he concludes.

Considering every element

Innovation