The International Energy Agency is forecasting both a potential doubling of global energy demand by 2050, against 1990 levels, and the need to halve CO2 emissions within the same timeframe.

For business and industry, energy consumption is in evidence everywhere, whether fuelling wastewater treatment, cement production or food processing. Costs are rising, traditional resources dwindling and the regulatory net is tightening.

In Europe, the 2013 EU Directive on Energy Efficiency requires all non-small and medium-sized enterprises, employing more than 250 people, to complete an energy audit or have a certified energy management system in place by December 5, 2015. The clock is ticking.

HOLISTIC, STRATEGIC, CONTINUOUS

While many businesses are starting the energy management journey from scratch, even established firms with long-term strategies struggle to meet the ongoing demands of providing dedicated staff with the process and energy-efficiency expertise required to maintain on-premise energy management systems.

This is driving a strong trend to seek out companies who can provide a remote service capability. Using hosted, cloud-based collection and analytics software as a foundation, remote service experts can monitor and improve the energy equation through a holistic approach, including procurement and consumption efficiency, as a partner to the business.

Using hosted, cloud-based collection and analytics software, remote service experts can monitor and improve the energy equation through a holistic approach

As a global specialist in energy management and sustainability, established in 1836, with €23.6-billion annual sales, Schneider Electric delivers energy management expertise through cloud-enabled remote services and software to clients in manufacturing and consumer packaged goods industries, as well as mining, cement, water distribution and treatment, smart cities, commercial buildings, healthcare, data centre, and transportation sectors.

Schneider Electric’s life cycle approach takes a holistic view of sustainability, energy supply and energy demand. It helps target key strategic opportunities, based on a company’s existing programmes, to deliver best-in-class results and sustained efficiencies. It considers people and systems issues combined.

Clients move from initial consumption awareness via analysis to optimisation and then on towards establishing a culture of continuous energy improvement called lean energy management.

The first step on this strategic energy journey, however, begins with identifying where on the map you start. Vice president of digital energy services at Schneider Electric, Michael MacKenzie, explains: “Often the difficulty in developing a core energy management strategy is a lack of visibility into the full energy story of a facility. Getting insight into how energy is being consumed, what normalising factors create inefficiencies and how wastes, such as emissions or effluents are managed, is critical to understanding how human behaviour has an impact.

“Data is frequently collected using utility bills and spreadsheets making it difficult to correlate energy events with production events inside a plant. The proper data capture strategy can turn raw data into information and information into wisdom, enabling continuous improvement strategies.”

Ultimately, there need be no more mystery to energy, than any other bill of materials (BOM) item, says Luigi De Bernardini, a systems integrator at Autoware. “Energy has to be a raw material in the BOM. It needs to be seen just as one of the factors to determine performance. The same benefits from continuous improvement initiatives, mobilisation, real-time data availability that apply to production performance, apply to energy performance,” he says.

DRIVEN BY MEGA TRENDS

Interest in Energy Management as a Service (EMaaS) is currently being driven by four mega trends in the industry:

• Need to translate big data into business value;

• Increased regulation and tax;

• Moves from capital expenditure to operational finance to reduce up-front costs;

• A lack of trained, dedicated energy management resources.

Coming off the back of a recession, business capacities and capabilities remain stretched to the limit in many areas, not least human resource, with effects felt keenly at site level. Plugging the skills gap is where remote energy management brings significant strategic benefits.

As mega-trends in the labour force are effectively leaving many sites with a skills shortage, particularly around energy efficiency at process level, energy management becomes one of many hats for site operational engineers. Remote monitoring and remote analytics services can reduce the amount of time site staff need to spend looking for patterns, anomalies and root causes of over-consumption in their data, giving them more time to focus on what really matters – meeting their targets.

In addition, corporate sustainability teams gain enhanced ability to spot anomalies between sites by benchmarking performance and using remote analytic services to hone in on inefficiencies.

Solutions can also actually help create revenue and return on investment to drive agendas forward.

“We talk about business value with our clients, rather than just cost-savings and meeting regulations,” says Mr MacKenzie. “A complete energy procurement and efficiency strategy allows a business to better predict cash flows and hedge against market risk, while consuming less energy and reducing waste, without sacrificing production targets.”

FROM BOARDROOM TO SHOP FLOOR

For low-carbon business models to achieve the kinds of energy-management aspirations and targets that prove game-changers and win competitive advantage, the aims of the boardroom and abilities of the technical team must also be aligned. Mr MacKenzie sees direction and delivery as mutually dependent.

“Energy savings are surprisingly easy to achieve when an executive sponsor is teamed up with operational staff who have a shared understanding of the goals of a lean energy-management initiative. Leaders need to convey and demonstrate the importance of these programmes for the future health of the organisation,” he says.

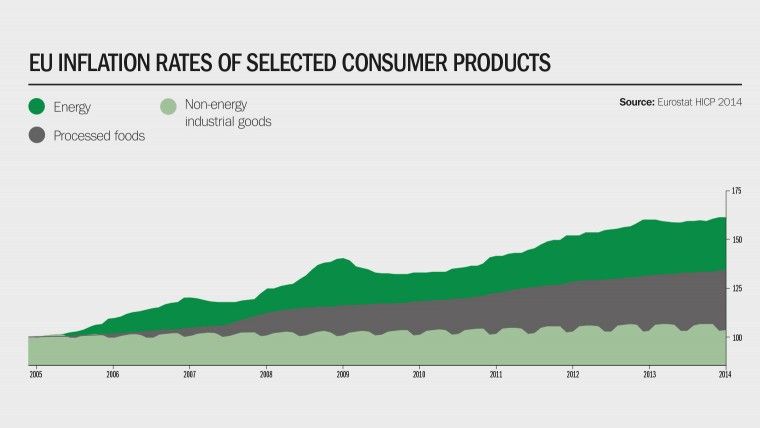

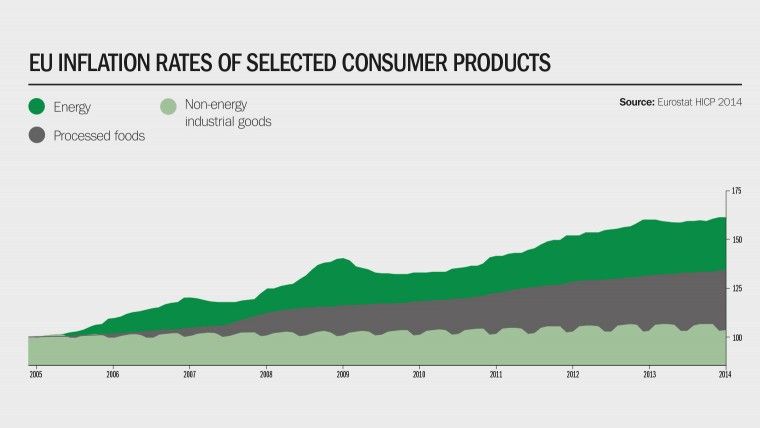

In many competitive industrial goods sectors, volatility and inflation in the cost of energy prove difficult to pass along to the end-consumer. Therefore, any business hoping to retain advantage will need to recognise and better control impacts of energy consumption.

Seeing energy management as an opportunity, not a problem, represents the way forward, Mr MacKenzie concludes: “Business leaders need to take ownership of their corporate energy equation and realise they can have a significant impact on the bottom line by managing energy as a controllable variable cost.”

HOLISTIC, STRATEGIC, CONTINUOUS