“Any customer can have a car painted any colour that he wants so long as it is black,” Henry Ford famously said. The great industrialist would be shocked by today’s demand from consumers for personalised products and services.

A survey conducted last year for Deloitte revealed that around two-thirds of those asked were aware of the possibility of customising products such as clothing (64 per cent), furniture (63 per cent) and fashion accessories (61 per cent) while the figure for footwear was 56 per cent.

Mass customisation is putting huge pressure on supply chains as companies work to ensure they can offer customers sufficient permutations of a particular product and a variety of delivery options. Meanwhile, firms in all sectors are also looking to reduce inventory to avoid tying up capital in stock.

It’s a dichotomy that Sara Gifford, chief solutions officer at Quintiq, a leading provider of supply chain planning and optimisation software, sees first hand.

The ability to optimise data in real time to change your plans as you react to customer demand is critical as it allows you to drive down inventory, even when offering increased possibilities for customisation

“Food and beverage manufacturers are particularly affected at the moment,” she says. “Take brewing. Some of the big household names in beer have acquired new microbreweries. The microbrewery market is exploding right now and it’s highly profitable, but acquiring a niche brand requires a complete change in the way in which these large companies approach production.

“They aren’t going to give up on their well-established money makers, so they have to work out how to add into their production suites much smaller rounds of a specialist product.”

For a growing number of manufacturers mass customisation introduces similar complexities as they have to consider how to schedule the different resources that are needed at various points in the production process of a wider a range of products.

Option one is to ensure they have what they need by simply increasing the inventory, but this is costly and reduces their ability to respond quickly to changes in the market. The second option involves having minimal parts and accessories ready and waiting for use. This cuts inventory costs, but it reduces the opportunities for customisation as the product nears completion in its journey along the production line. Stocks are more likely to run out, too, threatening lead times.

Meanwhile, customers are also increasingly demanding and impatient with delivery times.

“The ability to optimise data in real time to change your plans as you react to customer demand is critical as it allows you to drive down inventory, even when offering increased possibilities for customisation,” says Ms Gifford. She points out that following the excitement a few years ago over the emergence of big data, attention is now turning to what can be done with this data.

“Analytics is the key,” she says. “You’ve got those ones and zeros sitting on a machine, but now what do you do with them? Companies have all of this data drawn from the production process. This might include the way in which various intermediate inventory points flow through their supply chain. With effective analytics you can interrogate your big data and get usable information.”

Quintiq technology can now use big data to identify the precise points during the production cycle at which the manufacturer should be holding inventory ready for use. As a result manufacturers can respond cost effectively to customer demands. And these increasingly accurate forecasts make for an even leaner inventory.

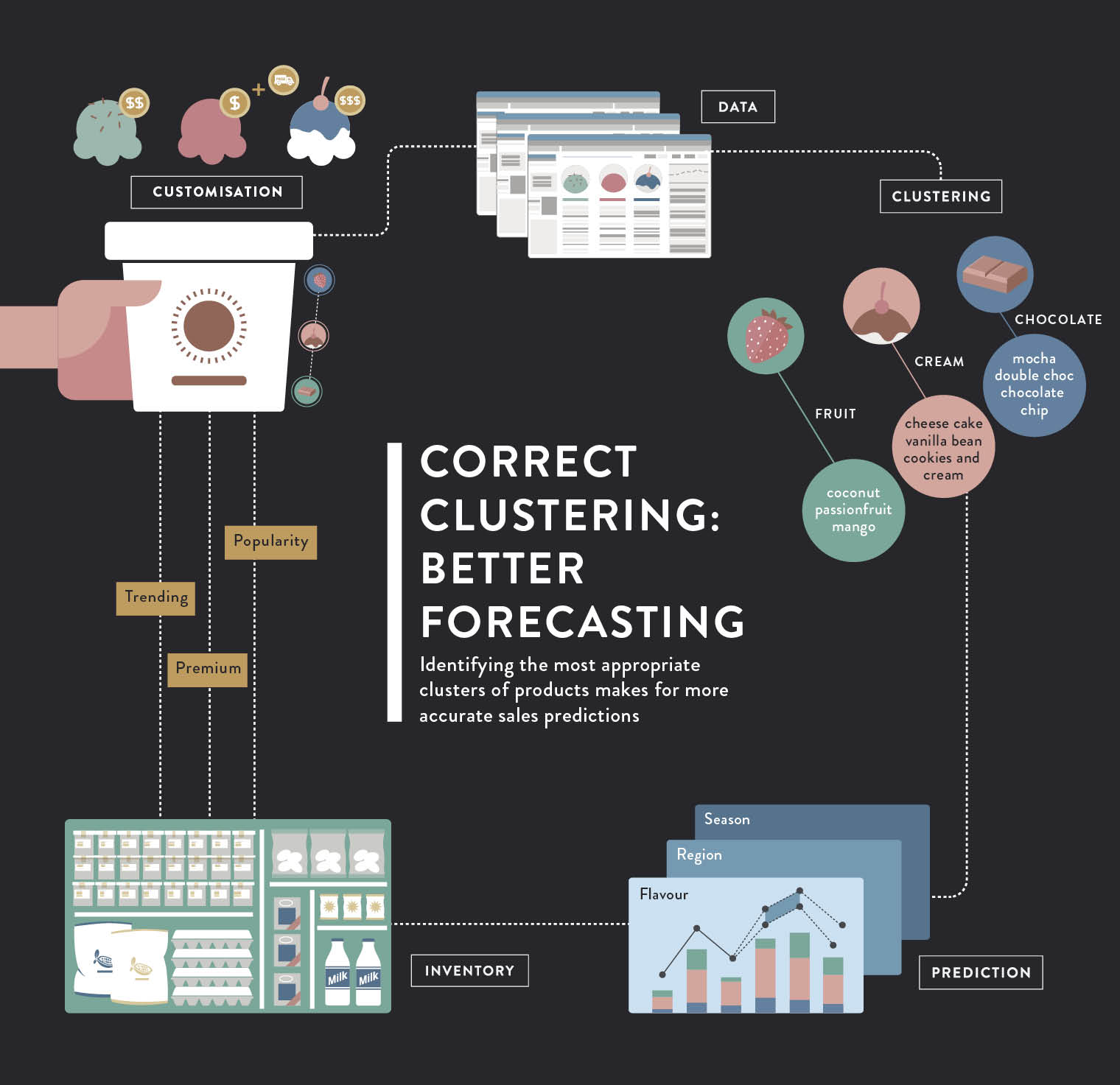

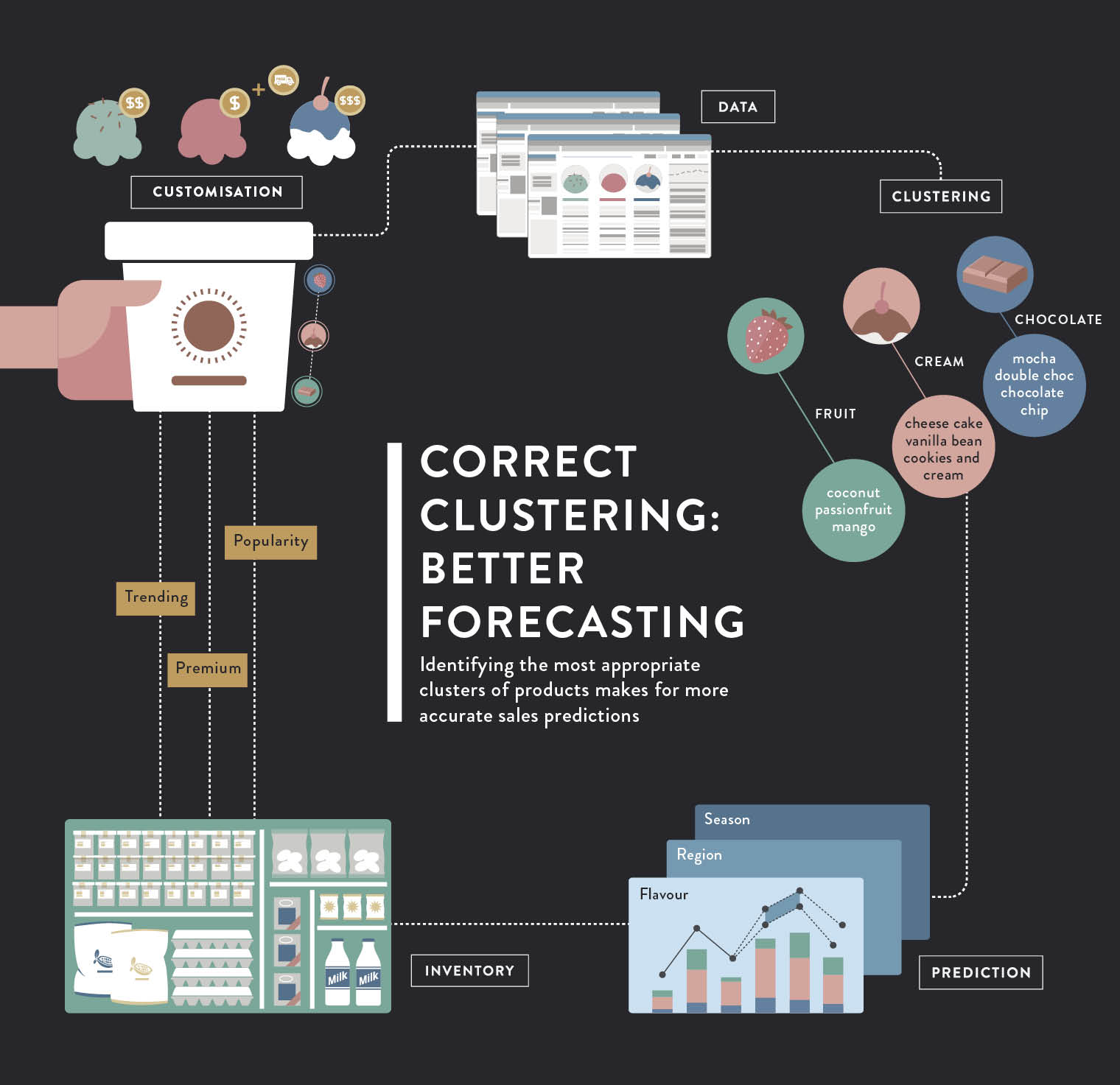

Trying to make predictions from every single product line would be too confusing with too many outcomes and so products should be grouped. How, though, do you identify the right groups?

“A paint company, for instance, with an industrial and a domestic division might be tempted to create product groups for forecasting purposes along these lines,” says Ms Gifford. “But this allocation might not create the most accurate forecasts. Instead it might be better to divide groups into vinyl, matt and metallic or to create clusters of colours such as blues and reds.”

Quintiq technology can identify how best to cluster products and at what level of granularity in order to produce the most accurate forecasts. More accurate forecasting means more efficient inventory management.

Big data analytics can also be used for influencing customers. “Airlines have been doing this for years, but it’s now creeping into manufacturing,” says Ms Gifford. “When I go online to book a flight, the airline will influence my decision about when I fly by the price of the ticket. Factories are starting to do the same thing. You can lead customers into or away from a decision through price or other factors.

“Customers feel that they have personalisation during this process, but subconsciously they’re choosing something because they can get it faster and perhaps cheaper. For instance, I might only really want the silver version of an iPad if I can get it in a few days. If it’ll take three weeks, then I’ll be happy with another colour instead.”

Companies can influence customer behaviour to improve costs in their supply chain. “But you need to be able to respond quickly and that’s where real-time optimisation and just-in-time scheduling come into effect. It can only work if you use this with proper analytics of your big data,” she says.

However, there is considerably less data available from the growing number of these new products driven by increasing customisation than there is with long-standing, best-selling items. The good news is that big data analytics allows manufacturers to start learning from much less data because the software can identify trends earlier than humans can.

“We’re going to see more product customisation based on agile responses to the changing market,” Ms Gifford concludes. “Companies that are able to predict quickly and accurately where the market is going can react equally quickly and accurately to make changes to their supply chain. And that will determine the real winners in this exciting, but challenging, new world of mass customisation married with leaner inventories.”

For more information please visit www.quintiq.com