Much is riding on the UK’s manufacturing sector, the ninth largest in the world, and a pillar of the nation’s economic prosperity. But manufacturers are facing pressures on an unprecedented scale, not least from the relentless threat of overseas competition.

In a fiercely competitive global market, UK manufacturers are seeing their product margins being constantly squeezed. With many products becoming commoditised, they are looking for opportunities to differentiate themselves.

Servitisation, the transformation journey through which they can develop the capabilities they need to provide the services and solutions that supplement their traditional product offerings, is one way they can do this.

We have already seen the likes of Rolls-Royce, Xerox and JCB facing this situation, reaching the end of the current line in terms of what they can offer and embarking on a servitisation journey. A survey carried out at an IFS worldwide customer conference last year revealed that two-thirds of the companies in attendance were offering services as part of their offering. And they are seeing the light at the end of the tunnel.

However, transitioning from making a product to selling the capability of that product is not easy. At a basic level, servitisation goes beyond simply producing spare parts and consumables, with manufacturers offering scheduled maintenance tasks every quarter, or product repair or upgrade services.

At the highest and most effective level of servitisation, manufacturers are entering into formal contracts with their customers, forging much closer relationships, and sharing the risk and the revenue with them. At this level, manufacturers need to understand what their customers want to achieve and sell them the capability which enables them to do that. By providing their customers with this level of service, they are ensuring customers do not look at the competition. They are effectively trying to lock them in.

For many manufacturers their servitisation journey will require significant organisational change. For example, they may not have the best service organisation set up already. There may also be new regulations, new compliances, a need to invest in new equipment and technology in order to go out and service existing equipment. Some will need to create new departments and recruit new people, one of the biggest challenges for manufacturing today.

It has become increasingly difficult to recruit the right people into the right jobs and one of the underlying reasons for this is branding. Manufacturing needs to be rebranded to reflect the modern industry. Automation is helping companies to improve the efficiency of their manufacturing operations, but they need to attract talented people with analytical minds who can work with and interpret data – people who can innovate.

Manufacturers also need to recognise that in making the transition to servitisation it will take them longer to win new customers. They are no longer selling a piece of product they are selling the fact it can improve their customer’s efficiency by x per cent. It is a different type of selling, more a solution sell than a product sell, which requires a different approach and many will find it a challenge.

However, it is one they will have to overcome if they are to survive in an increasingly competitive global market, as one manufacturing customer of IFS, an electronics hardware producer, has discovered. Forecasts have shown that within six years their hardware sales will start to decrease and will never increase again. From a business point of view, how do they ensure they’ll still be around in five or ten years’ time? They have gone down the route of adding software which helps their customers control and manage the hardware, and that’s where they see their future revenue growth and new business opportunities.

Because UK manufacturers won’t be able to compete on price, they have to compete on service or capability rather than on actual commodity

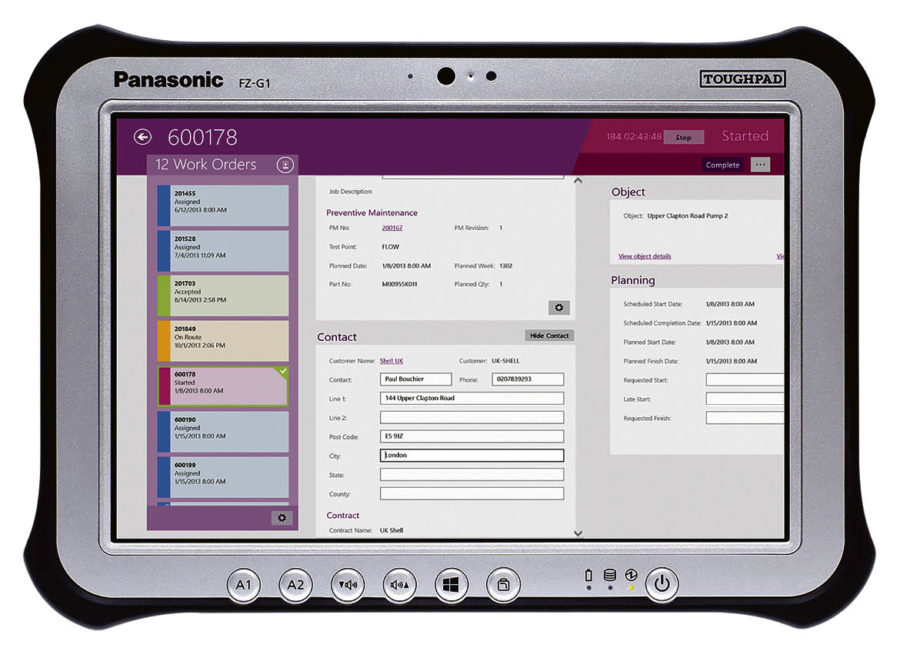

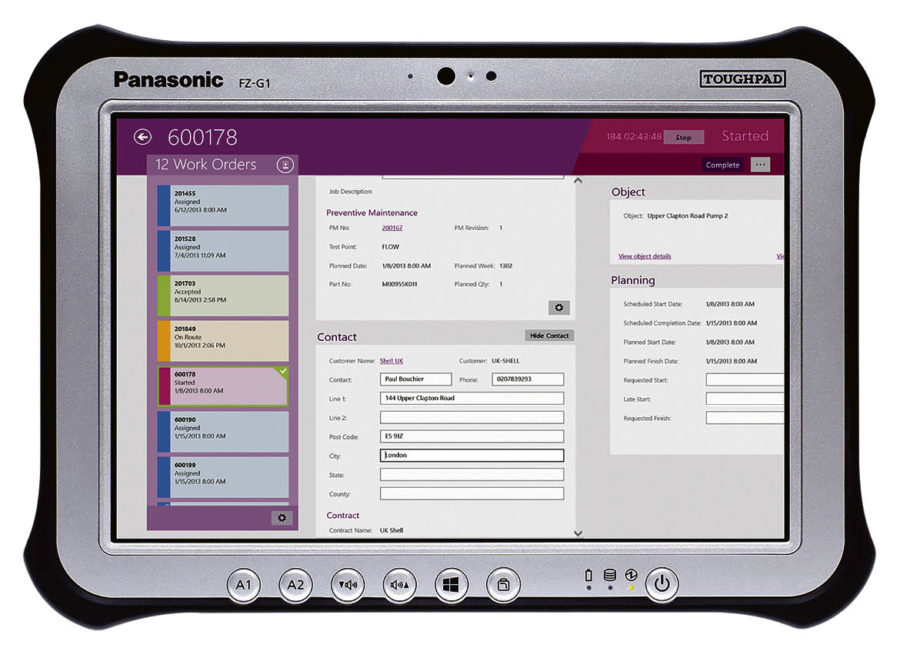

Manufacturers cannot make this change overnight. Before they can embark on their servitisation journey they need to know what options are available to help them achieve it and where to start. The relevant processes must be in place to deliver on the servitisation model, for example they need an enterprise solution that can handle what they are delivering to customers, the ability to record and control the type of service they are offering, and to schedule people, including sub-contractors, to perform jobs in the field.

This is where IFS is playing a pivotal role. As a provider of enterprise software, IFS works with manufacturers to help them design, make and sell. With fully integrated asset management field service contract capabilities, their customers know what equipment they’ve sold, how and when they are going to maintain it, and how to optimise the capability of the service they are offering to their customers.

IFS enables more effective through-life asset management, showing customers what and where something is happening within the production, supply and service life cycle – helping manufactures guarantee the end-goal for their customers who, in turn, have the reassurance they are effectively in it together.

If we are going to ensure the longevity of the UK’s manufacturing industry, we need to add uniqueness or increase competitiveness and this is where servitisation really comes into play. And it is something that manufacturers will have to do. Because they won’t be able to continue to compete on price, they have to compete on service or capability rather than on actual commodity. Their rewards will be more predictable revenue streams and greater stability, knowing there are no surprises around the corner.

Servitisation allows them to see what will happen next month, next quarter, next year – and it has to be the way forward for UK manufacturing.

For more information please visit www.ifsworld.com/times