UK buying habits are changing fast as consumers spend more time online and less time on the high street. The shift has seen profits for online retailers’ soar, but it has also presented them with major delivery problems.

Salisbury-based Test Valley Packaging is at the forefront of a drive within the packaging industry to design sustainable, cost-effective innovations that help retailers with the safe, efficient delivery of their products.

Michael Steedman, Test Valley’s marketing director, cites Black Friday as illustrative of the challenges retailers now face. Last year, the retail bonanza weekend in late-November saw such large volumes of online sales that retailers needed days, if not weeks, to catch up with orders.

“Of course, Black Friday is great news for packaging firms as demand for our packaging materials goes through the roof. But many retailers really struggle to sufficiently protect goods for shipping at the same time as achieving necessary throughput speeds at peak times,” he says.

Fast packing

Fast packing

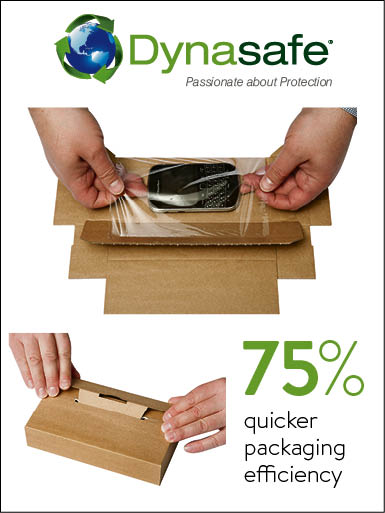

Dynasafe, Test Valley’s flagship product, represents an innovative response to e-retailers’ demand dilemma. The packing system revolves around the use of a low-slip, flexible film that easily accommodates a wide range of differently shaped fragile products. Whether it’s a glass bottle or a smartphone, the product is packed with zero fuss.

Adding to the efficiency of the process is the reduced requirement for “void fill” and other protective packing material. Test Valley has also designed a modular packaging system, which allows for products such as chinaware to be safely segregated – but, again, all with a minimum of additional labour and time.

Fast and easy unpacking is also factored into Dynasafe’s design. Test Valley prioritises simplicity of its retention boxes to avoid problems that consumers often face when it comes to opening packaging. Because Dynasafe contains no void fill or other packing materials, it is easy to recycle as well.

Sustainability

More online purchasing means more business for a packaging firm such as Test Valley. But it also means more cardboard and plastic, and therefore higher environmental impacts.

“We take environmental sustainability very seriously,” says Mr Steedman. “Not only do we feel minimising resource use is the right thing to do, but we’re finding that demonstrating our ‘green’ credentials is providing us with an edge in today’s market.”

With that in mind, the company has developed Dynasafe using environmentally friendly corrugated cardboard that contains 70 per cent recycled content and uses starch-based glues that are low in toxicity.

Another of the upsides of Test Valley’s retention packaging designs is the film technology they use. This offers an alternative to foam and polystyrene inserts, which add hugely to the environmental footprint of conventional packaging.

Recycling

Test Valley’s commitment to using recycled materials makes sense. Paper packaging can be recycled up to seven or eight times, while recycled paper requires 70 per cent less energy than paper made from raw materials. The firm is now in the final stages of developing a new ultra-compact machine to produce protective void-fill from recycled paper rather than plastic-based alternatives.

Recycling legislation poses a potential obstacle for many packaging firms, however. Under new regulations passed in 2014, corrugated board can have no more than 1.5 per cent “unwanted” content by weight if it is to be recycled in its entirety. Dynasafe packs meet these criteria. Test Valley is currently innovating with newer materials, ensuring its packaging continues under this threshold into the future.

“We expect Dynasafe will be changing the future of packaging for online fulfilment companies. For the first time, retention packaging with all its benefits will be accessible to online retailers at a cost comparable to traditional forms of packaging,” says Mr Steedman.

With Black Friday growing in popularity year on year, Test Valley will have no shortage of opportunity to put its technology to the test.

For more information please visit www.testvalleypkg.co.uk