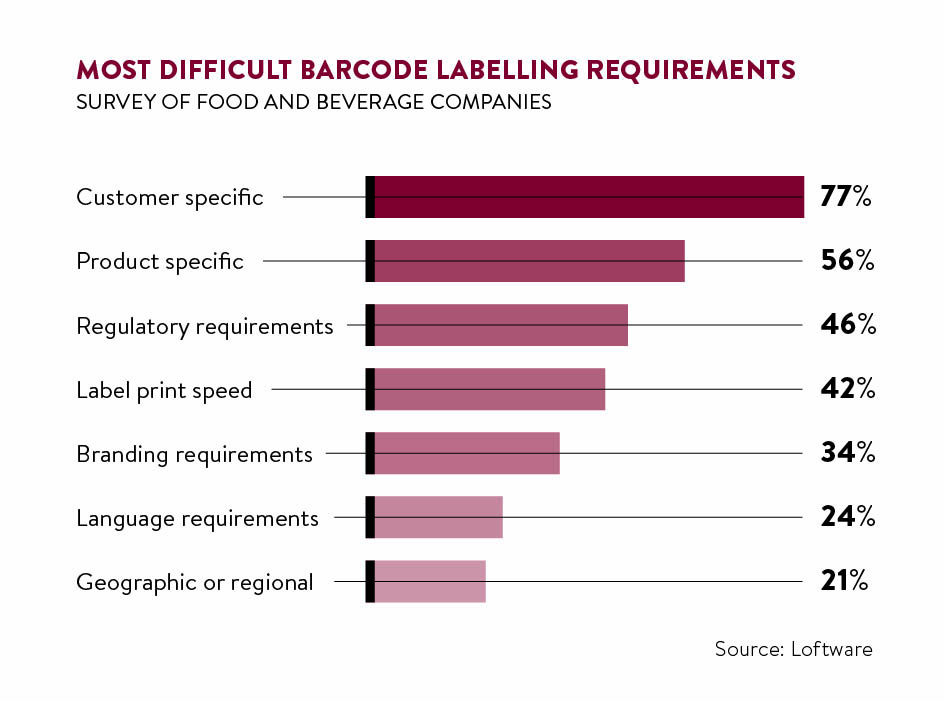

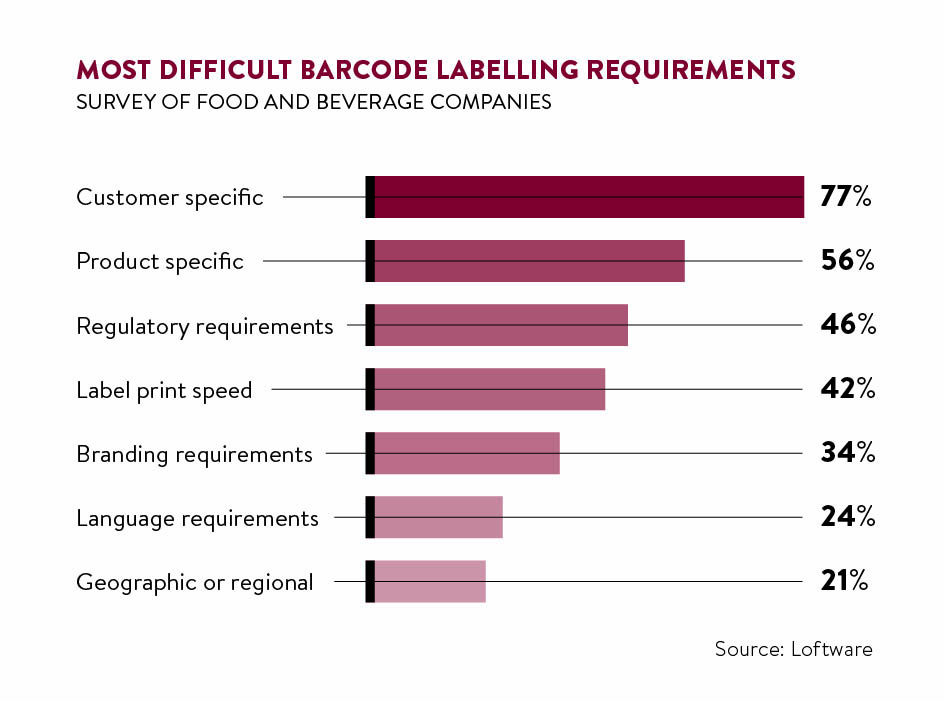

Correct labelling is vital for successful supply chain management – and yet it’s often fraught with problems. According to a survey published in December by Loftware, the enterprise labelling solutions provider, nearly half of those companies asked (47 per cent) experienced significant and costly disruption to their manufacturing process because of their labelling procedures.

“Leaders in supply chain management are often aware of only a sub-set of a growing number of labelling demands that can impact their global operations. The set of stakeholders is diverse,” says Josh Roffman, Loftware’s vice president of product management. “Each of these groups has their own perspective and set of priorities as it relates to labelling.”

New tech to the rescue

The good news is that labelling has become one of the fastest-growing, most innovative parts of supply chain management. New technology in particular is creating more accurate and increasingly informative labelling products that can be deployed evermore rapidly.

“When label printing in the enterprise supply chain goes wrong, the consequences are not only financial,” says Richard Hughes-Rowlands, product manager at Zebra Technologies, which creates tracking technology. “Misplaced shipments and delays also mean dissatisfied customers.” He sees more businesses turning to cloud label printing as a solution. “Those that have implemented it have realised significant savings and made their supply chain more agile, responsive and competitive,” he adds.

Walid Darghouth, Perfect Package solution director at Dassault Systèmes, says: “New markets, new variants and new pack sizes create the need to develop artwork faster, and this puts enormous pressure on product copy, translations and regulations. The current artwork supply chain is highly fragmented, leading to increasing errors. In fact, these errors drive 51 per cent of product recalls, often costing millions of dollars each.”

Dassault Systèmes’ Perfect Package allows packaged goods companies to improve the quality of their artwork by reducing costs. Many organisations still manage their copy in word documents or spreadsheets that are scattered around the company and this makes producing new artwork difficult. By managing the process centrally, including copy development, translation and artwork, Perfect Package integrates the copy management and artwork creation process, enabling companies to create new label designs in just 24 hours.

A product called Thinventory (pictured above), developed by tech company ByBox, provides labelling in which SKU (stock keeping unit) codes are captured at the point of dispatch so the relevant items can be traced live online through picking, packing and distribution, as well as returns and repairs if necessary.

“Any supply chain consists of a number of key players – manufacturers, suppliers, warehouse operators, distribution providers, technicians, end-users – and so on. Each system requires its own label. Technology tends to get smaller every year, so over time it was becoming physically impossible to fix all the labels from all systems on to the packaging,” says Stuart Miller, chief executive and co-founder of ByBox. “We introduced Thinventory to sit across the entire supply chain and run it not only with one label, but one single barcode on that label.”

Protecting and authenticating products

The challenge of accommodating a number of barcode labels, relating to information such as quantity and serial or batch number was addressed in August when some of the UK’s largest retailers and suppliers, including Boots, Morrisons and Nestlé, launched a new initiative to use barcodes provided by GS1 UK, the supply chain standards organisation, to develop a set of industry standards for inbound logistics.

“As these organisations pass the use of GS1 barcodes on product labels down through their supply chain, it’s only a matter of time before having GS1 barcode support within warehouse operations becomes essential,” says Karl Blakesley, marketing consultant at OrderWise Business Management Software, a GS1 UK industry partner.

Labelling technology can also now protect goods. Shockwatch labels contain a tiny glass device filled with liquid. If a package is subject to excess impact during transit, the liquid turns bright red. Tiltwatch performs a similar role for packages that should be kept upright.

With increasingly complex supply chains, correct labelling is vital

It’s estimated that one in every ten cigarettes in the world is illegally produced, while in 2014 illicit spirits were estimated to cost governments around $1,020 billion in lost revenue. To solve this growing problem De La Rue, the world’s largest commercial banknote printer and passport manufacturer, has developed a unique global tracking code called DLR Certify. It enables its customers to authenticate, validate and trace their excisable products, helping governments and businesses to ensure the correct level of revenue has been paid and that products are genuine.

“Companies don’t fully understand the scale and nature of the security issues they face in the supply chain,” says Andrew Gilbert, business development manager for authentication and traceability at De La Rue. “From overproduction, to diversion, to sales through non-licensed producers or even smuggling, the range of threats in the supply chain continues to diversify.”

“Companies don’t fully understand the scale and nature of the security issues they face in the supply chain,” says Andrew Gilbert, business development manager for authentication and traceability at De La Rue. “From overproduction, to diversion, to sales through non-licensed producers or even smuggling, the range of threats in the supply chain continues to diversify.”

So far labelling has been a case of applying an authentication feature on to an item, to confirm it is a genuine product belonging to a particular brand. This can address the issue of counterfeiting. However, in today’s globally connected and complex supply chain, opportunities for interference, tampering and diversion into unauthorised markets are rife, particularly where there are large price and tax differentials, says Mr Gilbert.

“Faced with this set of challenges, a more sophisticated approach to tackling illicit trade is required, addressing the three pillars of track and trace, verification, and authentication,” he says.

With increasingly complex supply chains, correct labelling is vital. “The need to meet customer and regulatory requirements can be either a burden or a source of competitive advantage. The easier it is to quickly make label changes, the more able companies are to respond to the demands of customers and regulators,” Lofware’s Mr Roffman concludes.

New technologies entering the market mean companies have a greater range of options than ever before to ensure their labelling meets these challenges.

CASE STUDY: CHOICE MEATS

Blackpool-based fresh and cooked meat supplier Choice Meats delivers around 160 orders a day to more than 400 trade customers across north-west England.

Blackpool-based fresh and cooked meat supplier Choice Meats delivers around 160 orders a day to more than 400 trade customers across north-west England.

Operating the business efficiently requires a well-run order management and labelling system. For years the business labelled orders using printers attached to two large weighing scales, but this was creating a bottleneck.

“They were big, bulky machines that couldn’t easily be moved around the warehouse, so constant trips were being made back and forth between the goods for dispatch and the printer, costing a lot of time,” says Paul Fleetwood, office manager at Choice Meats. “As we continued to expand, it became clear that we needed to upgrade our capabilities to keep pace with the number of orders we were handling each day.”

To address these issues, the business upgraded to four Brother TD-2120N professional industrial label printers. The units weigh just 1.3kg and can print 5.6cm-wide adhesive labels at speeds of up to 15cm per second.

Mr Fleetwood says: “The Brother units have solved both of the issues we had when using the scales. They’re able to store all of our customer information, so operators can simply type a four-digit code into the touchscreen display and the printer will prepare a label including the customer’s name and address along with the order date, a Julian encoded packing date and our logo.

“While they operate independently most of the time, which was a key concern for us, they also work hand-in-glove with our PC-based customer database, so adding new customers or updating details is a quick and simple operation.”

New tech to the rescue

Protecting and authenticating products