Big data analytics has permeated every aspect of business life with all sectors affected by a technology that is revolutionising the way in which companies understand their customers’ behaviour and adapt their operations accordingly. The market intelligence service IDC forecasts the big data technology and services market growing at a CAGR of 23.1 per cent between 2014 and 2019 with annual spending reaching $48.6 billion in 2019.

According to research from the Massachusetts Institute of Technology, companies that use it enjoy productivity and profitability that is 5 to 6 per cent higher than that of their peers.

For many, though, the way big data is being used means it still isn’t providing business leaders with all the insights and useful information that it could do. A report by Bain & Company found that only 4 per cent of companies are using it properly.

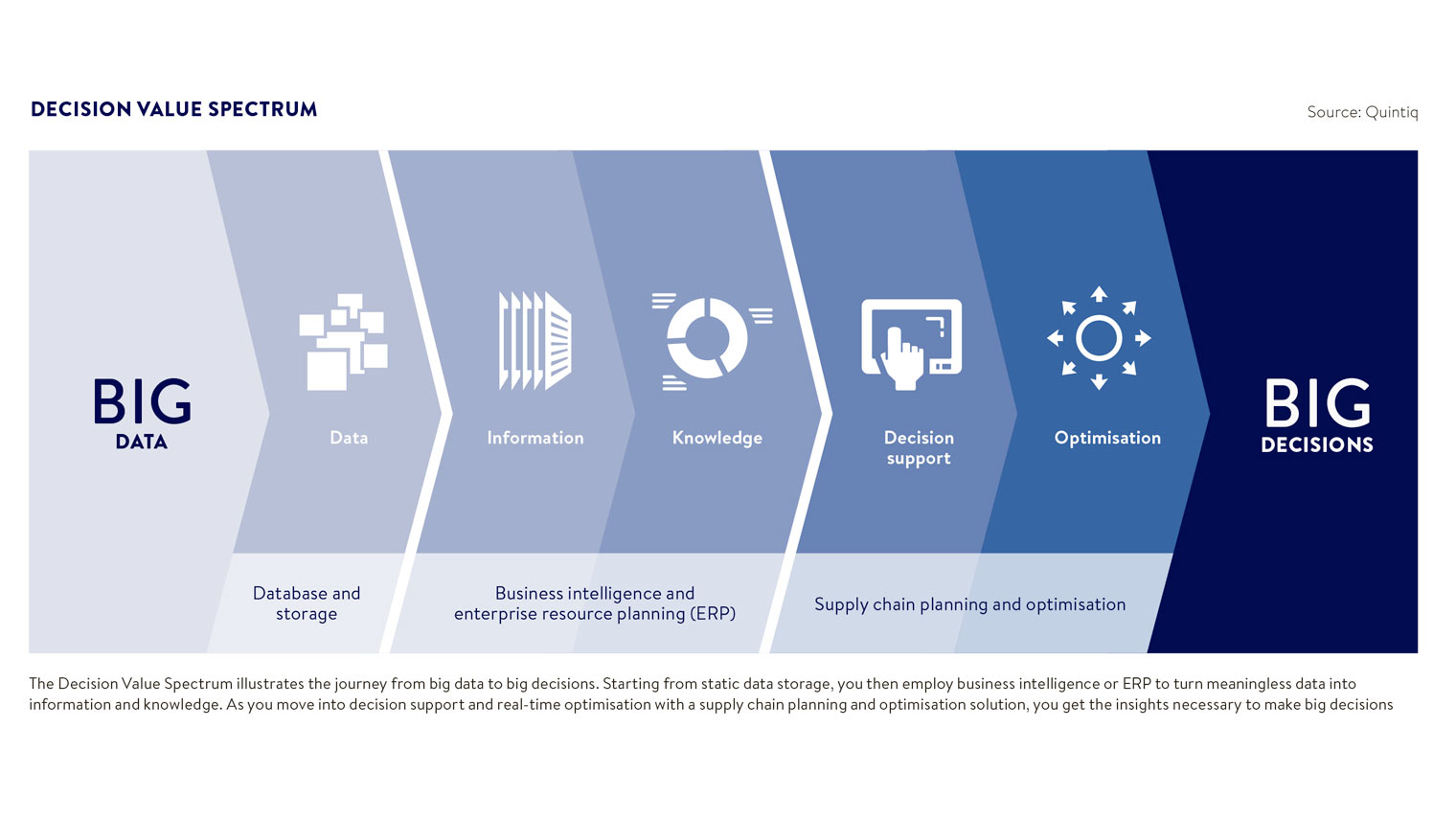

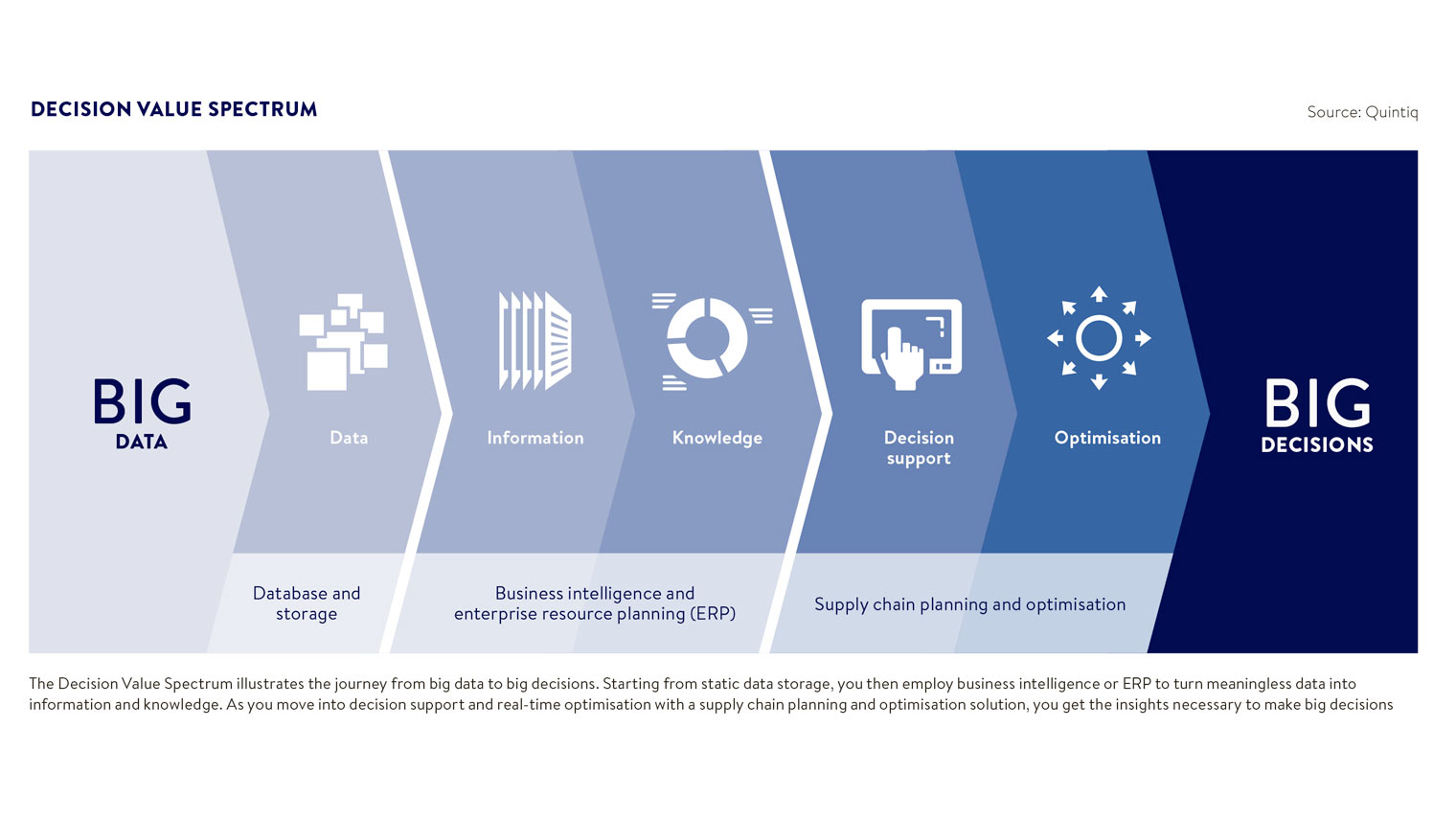

We say that it’s not about big data; it’s about big decisions

Certainly this is true for many players managing complex supply chains, according to Rob van Egmond, chief executive of Quintiq, a leading provider of supply chain planning and optimisation software. He has encountered too many business leaders who are looking at analytics back to front, focussing on the huge quantities of data available rather than thinking about what they want to achieve with it.

Rob van Egmond

Chief executive

Quintiq

“We’re educating companies, helping them to understand that the key to success is not about processing, or even analysing, large volumes of data,” he says. “Business leaders need to start using analytics technology not just to learn, see or understand, but to make better decisions. We say that it’s not about big data; it’s about big decisions. When you focus on overcoming business challenges, you can analyse the relevant data to produce the necessary insights, giving your decisions a much stronger foundation.

“Used properly, analytics allows you to model what is actually happening in the supply chain. Real-time operational data allows you to make decisions and plans based on the current reality, rather than just the assumptions or observations of people within the company.”

This holistic overview allows for better decision-making. For example, managers can decide whether to accept an order or not and avoid either taking one that the company cannot fulfil, thereby damaging its reputation, or refusing one which it could, in fact, handle – a decision that could result in lost revenue.

Very importantly, it can also be used to forecast demand and other factors. “Supply chain management is all about making predictions and then making the right decisions based on what you’ve predicted,” says Mr van Egmond. “Getting this right means that you’ll be able to run a lean and effective organisation.”

In a recent survey of Quintiq’s customers, nearly three quarters of respondents agreed that supply chain analytics’ value lies in its ability to deliver increasingly accurate demand forecasts. Those forecasts are accurate because of a deep, wide understanding of the data, and it’s increasingly accurate thanks to the application of machine-learning, which increases the system’s understanding over time.

As “now culture” becomes the norm, customers expect to be able to place an order in the morning and receive their goods that same day. Mr van Egmond points to how supply chain analytics, combined with optimisation, is improving the reliability and profitability of same-day delivery for Quintiq’s customers in retail.

“For same-day delivery to be good business, retailers need to understand precisely when and where demand will come from and how they can meet it,” he says. “You can then steer your customer – with dynamic pricing – towards that time of day at which you know that you can deliver efficiently on an optimal route. Supply chain analytics combined with real-time optimisation is essential as the supply chain speeds up and there’s less time for discussion or typical human decision-making processes.”

Founded in 1997 by five computer programmers, Quintiq has grown rapidly and today global organisations across 80 countries use the company’s services to plan and optimise their workforce, logistics and production. In postal logistics, it supports the distribution of more than a million parcels worldwide every day.

A key element of its philosophy is Quintiq’s single platform. “We’ve seen too many products in the analytics sector that either focus on the manufacturing or the logistics and leave it up to the company to somehow integrate the two,” says Mr van Egmond. Built to fit any business model, the Quintiq platform covers both manufacturing and logistics, supporting business leaders in making decisions that benefit the business as a whole.

Exciting new developments include the use of artificial intelligence and machine-learning, both of which are offering continuous improvements on the shop floor as well as predictions into what might happen to a supply chain in the future. With analytics, companies will soon offer differential and thus individualised pricing, Mr van Egmond believes.

“When you book a flight, you notice a variation in prices and this, of course, depends on demand. The same idea can also offer real advantages to businesses,” he says. “For instance, whether it’s manufacturing or logistics, you can reduce your price when demand is low and increase it when demand picks up. You might offer a customer a lower price if they can wait a few days for their order to be delivered because you know you’ll have capacity to spare then. But you can only do this if you have an accurate view of your supply chain and know how the market is going to behave.”

Not only does effective supply chain analytics offer significant competitive advantages, but implementing it is cheaper and faster than many enterprise resource planning suites. The majority of customers can start by simply looking at the bottlenecks in their supply chain and benefit by initially focusing resources on these, says Mr van Egmond. The benefits, he explains, can be realised within a two-to-three-month time frame.

“We find that with a lot of customers, these savings can then be used to finance future investment and improvements,” he says. “Used correctly, supply chain management analytics offers companies huge benefits both now – and in the future.”

For more information please visit www.quintiq.com